Electrical Systems

Non invasive inspection to identify overheating, poor or loose connections

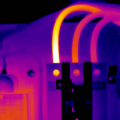

Inspecting Electrical Equipment

Thermography or Thermal Imaging Surveys are non-contact and non-disruptive, in fact they are best carried out when the equipment is in use to get the maximum benefit from the inspection.

From small Domestic to large Industrial or Commercial consumer units, fuse boxes and distribution boards, thermal imaging is a very effective way of identifying faults.

Many electrical faults start to develop long before they are visible to the naked eye.The standard method for inspecting electrical equipment is to isolate the equipment from the electrical supply before manually checking connections and the operation of moving parts, and to look for any visual signs of heat build up.

A build up of heat is often the first sign of a fault, but is not detectable with the naked eye, and having switched off the equipment to use traditional inspection methods, the heat soon dissipates leaving no evidence of the problem.

However the use of a cost effective, sophisticated, thermal imaging camera, the equipment is surveyed LIVE under normal working conditions. This shows exactly where there is an unexpected heat build up, which could potentially lead to equipment failure, costly repairs unplanned downtime and even FIRE.

Early detection allows the fault to be rectified before further damaged is caused and at a time that is convenient to the user.

Types of equipment recommended for regular Surveys:

Consumer Units, Fuse Boxes and Distribution BoardsControl PanelsLighting and lighting control equipmentSwitches and power outletsElectric Underfloor HeatingGeneral Heating equipmentCooking equipmentRefrigeration equipment