Mechanical Equipment

Non invasive method of inspecting moving parts from a safe distance

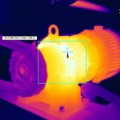

Inspecting Mechanical Equipment

The inspection of mechanical equipment can often involve lengthy downtime involving removing guards, covers and sometimes dismantling parts to gain adequate access to visibly inspect bearings and other moving parts.

The use of Thermography or Thermal Imaging means surveys can be carried out without having to stop production. The surveys are carried out in a fraction of the time and offer a very cost effective interim inspection that can be carried out between planned maintenance.

Anything from gear boxes, bearings, motors, pumps, lubrication systems, cooling systems and heating systems all produce detectable heat patterns so unusual hot spots could indicate a problem that could lead to premature and costly failure if left undetected and not repaired.